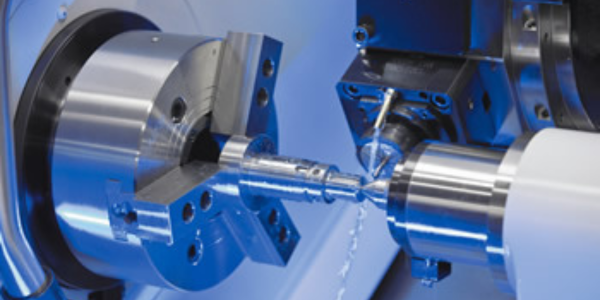

Turn mill parts play a crucial role in various industries, including automotive, aerospace, and medical. As a trusted and leading provider of high-quality Turn Mill Parts India, turn mill components, and turn mill machining services in India, we pride ourselves on utilizing advanced machinery and cutting-edge techniques to deliver exceptional precision and durability. Designed to perform multiple operations such as milling, drilling, turning, and threading in a single setup, our turn mill parts streamline production processes, reduce lead times, and enhance overall efficiency.

We take immense pride in being your trusted partner for all your turn mill needs. With a legacy of excellence and a commitment to precision, our state-of-the-art facilities and experienced professionals ensure top-notch results in every project.

More DetailsOur CNC turn mill job work is renowned for its exceptional accuracy, efficiency, and reliability. Leveraging advanced computer numerical control (CNC) technology, we excel in a wide range of turning and milling operations across diverse materials, be it metals or plastics. Our skilled technicians bring an unwavering dedication to executing every project with meticulous attention to detail.

Utilizing turn mill parts offers numerous benefits, making them a game-changer in modern manufacturing. Let's explore some key advantages:

♦ With the capability to perform multiple operations simultaneously, turn mill parts significantly reduce production time and increase overall throughput. This leads to higher productivity and cost-effectiveness for businesses.

♦By eliminating the need for multiple machine setups, turn mill parts ensure superior accuracy and consistency. This precision translates into high-quality finished products, meeting even the most stringent requirements and specifications.

♦ Turn mill parts accommodate a wide range of materials, including metals, plastics, and composites. This versatility makes them suitable for diverse applications, providing flexibility in design and manufacturing processes.

♦By consolidating various operations into one setup, turn mill parts minimize material handling, tooling, and setup costs. This optimized process results in substantial cost savings for businesses, contributing to their bottom line.

We provide customized solutions that meet your specific requirements, ensuring tailored results for each unique project. Our stringent quality control measures guarantee products that adhere to the highest standards of reliability. With competitive pricing, we offer cost-effective solutions without compromising quality, while our efficient processes and committed team ensure timely delivery to meet your project deadlines. At the core of our business is customer satisfaction, prioritizing open communication, prompt responses, and proactive support for a smooth and hassle-free experience.

To learn more about our turn mill services, capabilities, and past projects, please visit our website. Our comprehensive website provides detailed information about our company, infrastructure, quality standards, and contact details to help you get in touch with our knowledgeable team. Contact Deccan Engineering Works today and experience the excellence of our turn mill services. We look forward to partnering with you to fulfill your machining requirements.

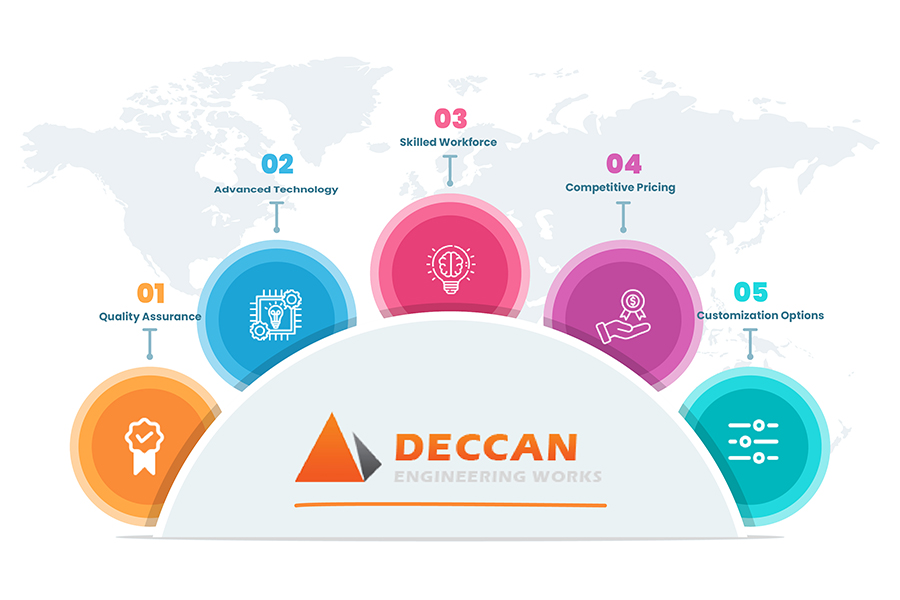

We adhere to stringent quality control measures throughout the manufacturing process to ensure that our machined parts and components meet the highest quality standards. Our team of experienced engineers and inspectors conducts rigorous inspections and tests to guarantee the reliability and performance of our products.

Equipped with advanced CNC machines, computer-aided design (CAD) software, and other cutting-edge tools, we have the capability to handle complex machining requirements. Our commitment to technological advancement enables us to stay ahead of the curve and provide innovative solutions to our clients.

At Deccan Engineering Works, we have a team of highly skilled and experienced professionals who are passionate about their craft. Our engineers and technicians possess in-depth knowledge of machining techniques and are dedicated to delivering excellence in every project.

We believe in offering competitive pricing without compromising on the quality of our products. Our efficient production processes, streamlined operations, and strategic partnerships enable us to provide cost-effective solutions that add value to your business.

We understand that every customer has unique requirements.That's why we offer tailored solutions and customization options meet your specific needs. Whether it's a one-off prototype or large-scale production run,we work closely with our clients to provide personalized services and deliver superior results.

Fill Out The Form for More Information