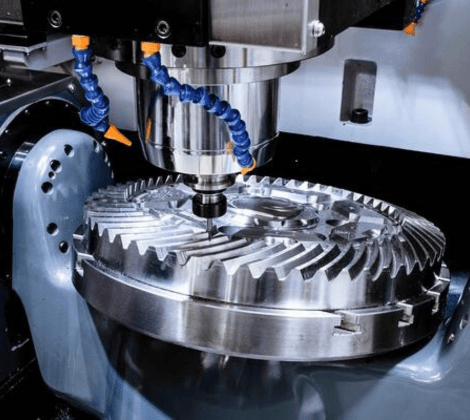

Precision 5 Axis Machining Solutions in India offers advanced manufacturing capabilities utilizing 5 axis machining technology. This cutting-edge process involves the use of a computer-controlled machine with five axes of motion to cut and shape materials. Compared to traditional 3-axis or 4-axis machines, 5 axis machining enables more complex and precise machining operations. It is particularly suited for the production of highly intricate and precise parts or components required in industries such as automotive, medical, and more.

More DetailsAt Precision 5-Axis Machining Solutions, we provide a comprehensive range of 5-axis machining services to meet your unique manufacturing needs. Whether you require prototyping, production runs, or customized solutions, our capabilities and expertise ensure results that surpass industry standards.

♦ Our precision machining services utilize state-of-the-art 5-axis machines to achieve unparalleled accuracy and versatility. By performing complex operations from multiple angles, we can produce intricate components with exceptional precision. From intricate contours to complex geometries, our machining capabilities are tailored to meet even the most demanding specifications.

♦ With our expertise in custom fabrication, we excel at turning your unique design concepts into reality. Our skilled team works closely with you to understand your requirements and delivers tailored solutions that align precisely with your specifications. Whether it's a one-of-a-kind prototype or a specialized component, we are dedicated to bringing your ideas to life with precision and excellence.

♦In addition to 5-axis machining, we provide comprehensive assembly and finishing services. Our meticulous approach ensures that every component undergoes thorough inspection, precise assembly, and impeccable finishing. With stringent quality control measures, we guarantee that the final product meets the highest industry standards.

1. Experience and Expertise in 5-Axis Machining: Look for companies with a proven track record and experience in handling complex machining projects.

2. Quality Assurance: Ensure that the manufacturer or supplier has robust quality control measures in place to maintain precision and accuracy in their machining processes..

3. Technology and Capabilities: Evaluate the company's machinery, equipment, and technological capabilities to ensure they can handle your specific requirements.

4. Industry Certifications: Check if the manufacturer or supplier holds relevant certifications, such as ISO 9001, which demonstrates their commitment to quality management systems.

5. Pricing and Lead Times: Request quotes from multiple companies and compare their pricing and lead times to find the best balance between cost, quality, and delivery.

By considering these factors, you can select a 5-axis machining manufacturer or supplier that meets your specific requirements for precision 5-axis machining solutions in India. Choose Precision 5-Axis Machining Solutions as your partner in precision manufacturing. Contact us today to discuss your specific needs and let us provide you with cutting-edge solutions that unleash the full potential of 5-axis machining.

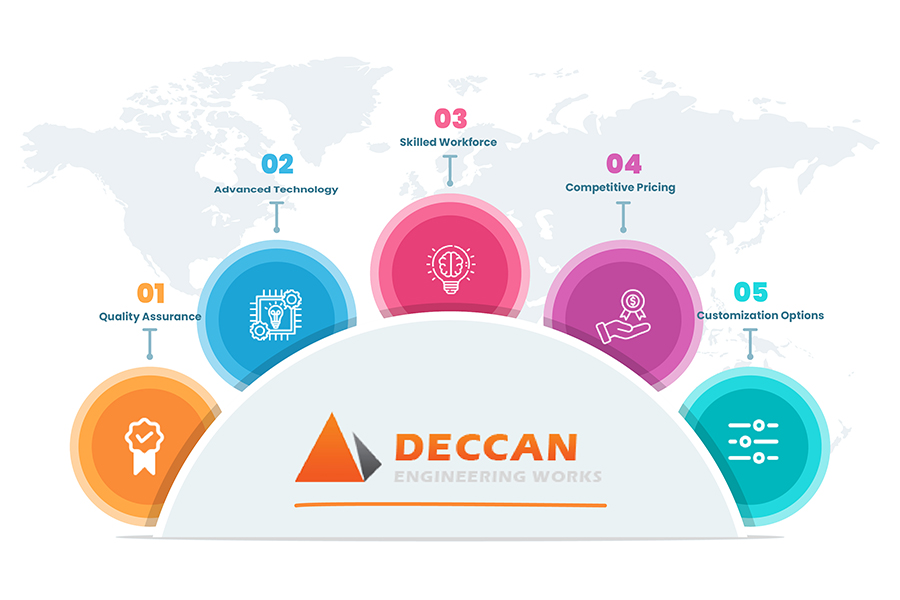

We adhere to stringent quality control measures throughout the manufacturing process to ensure that our machined parts and components meet the highest quality standards. Our team of experienced engineers and inspectors conducts rigorous inspections and tests to guarantee the reliability and performance of our products.

Equipped with advanced CNC machines, computer-aided design (CAD) software, and other cutting-edge tools, we have the capability to handle complex machining requirements. Our commitment to technological advancement enables us to stay ahead of the curve and provide innovative solutions to our clients.

At Deccan Engineering Works, we have a team of highly skilled and experienced professionals who are passionate about their craft. Our engineers and technicians possess in-depth knowledge of machining techniques and are dedicated to delivering excellence in every project.

We believe in offering competitive pricing without compromising on the quality of our products. Our efficient production processes, streamlined operations, and strategic partnerships enable us to provide cost-effective solutions that add value to your business.

We understand that every customer has unique requirements.That's why we offer tailored solutions and customization options meet your specific needs. Whether it's a one-off prototype or large-scale production run,we work closely with our clients to provide personalized services and deliver superior results.

Fill Out The Form for More Information